File to make it yourself: XG-100P-AccCover-v6.stl

Hardware needed: M3x6 hex cap screw

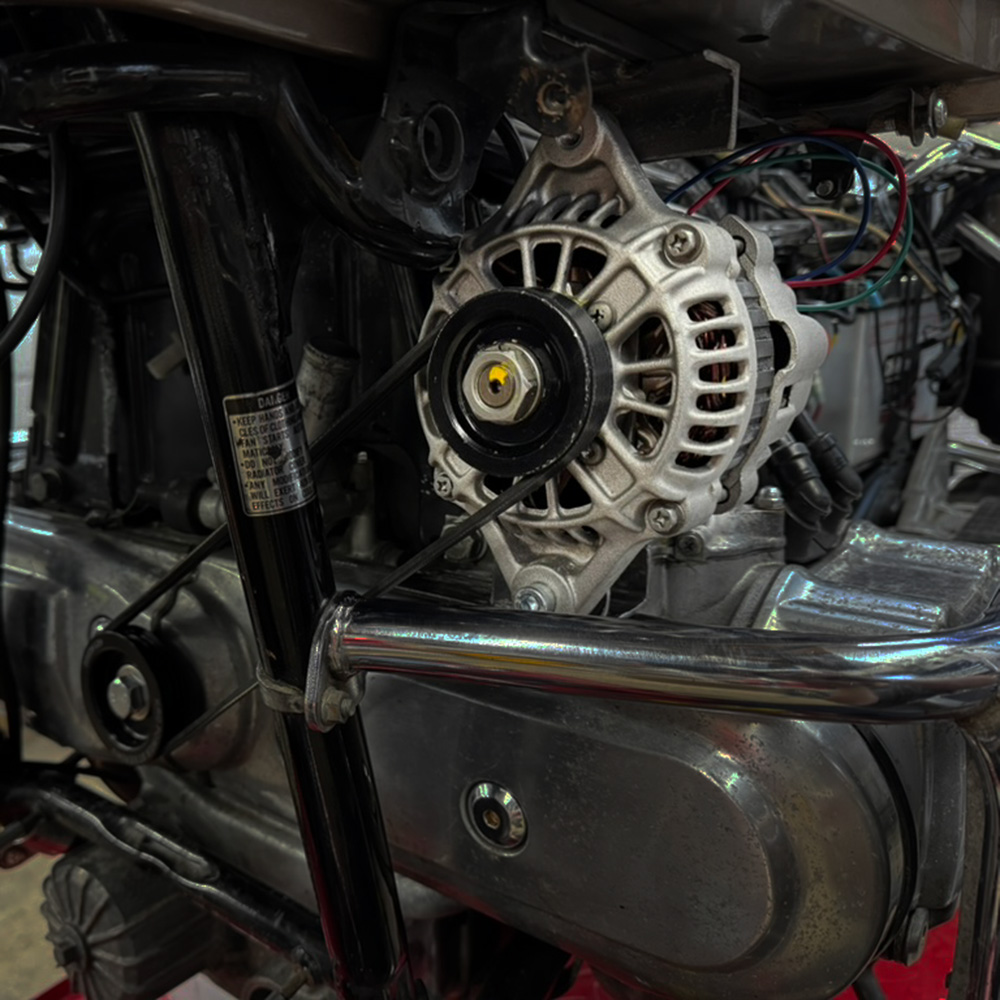

I just completed a poor boy alternator on my Honda Goldwing GL1200 Aspencade. I tried my best to document any tips and all the parts I purchased to complete the project below.

Youtube Video: https://tinyurl.com/poorboy-alt

This document uses affiliate links, and I earn a small commission when you purchase parts using the links on this page.

Finding the device ID for Exchange when you use the native mail app for iOS is fairly straightforward, but if you use the Outlook for iOS app, it is much harder to find.

I’ve discovered a process to uncover the device ID, because it appears to be hidden from the Outlook app alltogether.

See this screenshot from an Outlook App device in Exchange Online. Compare it to the one below it of a device added with the native mail app.

The native mail app gives you more detail, which can help you identify the correct device easier. The Outlook app has almost no information besides the iOS version which is usually outdated.

We can get the device ID from your device that uses the Microsoft Outlook App, but you need to perform some additional steps.

You will need a Windows PC with the Microsoft store to download the Microsoft Diagnostic Data Viewer The mobile device in question must be connected to the same Wireless network as the diagnostic PC. The outlook app will create a TCP connection to the PC to send logs.

Download Microsoft Diagnostic Data Viewer on PC

Go into Settings and enable Office diagnostic data viewing on, and Remote Office diagnostic data viewing on

Open the Outlook App and go into Settings>Privacy Settings>View Diagnostic Data on Windows

Copy the Office Connection String from the Diagnostic Data Viewer, and enter it into the Connection String field on the Outlook App.

Exit back to the main screen of Outlook, and check for new messages by pulling down on the Inbox screen. You should see your mobile device show up on the sidebar of the Diagnostic Data Viewer

Select this device, and you should see JSON debugging information. This localId matches what we see in Exchange Admin Center

If you own a DJI Smart Controller, you may have come across this message while trying to plug it in to charge.

Current charging speed slow. Please use the charger that comes with the device for a faster charging speed.

Slow charging a smart controller could represent a hazard, because the slow charge rate isn’t enough power to maintain the battery level while flying your drone.

After a recent incident where the smart controller shut down while I was flying a drone, I became determined to find a solution to be able to rapid charge the controller via a battery pack I already had

A forum post I discovered mentioned the controller used Qualcomm’s QuickCharge standard. Qualcomm’s QuickCharge standard is a pre-USB PD era charging standard that allows negotiated charging above 5v for supported devices.

I didn’t want to buy yet another battery pack just for an antiquated standard, so I opted to make a cable that converts USB PD to QC instead.

Parts list (Amazon Affiliate links):

Consumables I already had:

Tools:

Here is the final product:

The braided cord goes into the battery pack, and the barrel plug goes into the QC 3.0 adapter. This braided cord is the magic sauce that tells the charger to output 20v, and send that to the “yipin Hexha” adapter

That adapter will let you charge your Smart Controller significantly faster than before, and your controller won’t die while charging. Hope this helps!

I recently picked up a broken Sony bluetooth speaker locally for $20. Using a few resources I found online, I was able to easily fix the mainboard so it would turn on. Originally the speaker would show no lights at all, not respond to any buttons.

This seems like a common problem for this model, and this guide will hopefully help keep these surprisingly good sounding speakers out of the landfill.

IF you are not comfortable working with high voltage, and soldering electrical components, I am providing a repair service for anyone who wants their board fixed. Feel free to email me at [email protected]. We will need to do some basic troubleshooting to confirm the issue is indeed something I can fix.

(Note: Do this at your own risk. This guide may expose you to High voltage which is dangerous and I don’t take any responsibility for any damages, injury, or death).

To Fix it yourself, you will need to be skilled with a soldering iron, and have knowledge of basic electronic circuits.

Parts you’ll need (Amazon Affiliate links):

The problem with these speakers lies in the 5v power regulator IC and schottky diode. These components are prone to failure which causes the diode to dead short, and the IC to burn out. My thermal camera shows the 5v IC getting hotter than the rest of the board.

The power supply board provides 36v via a white and blue ribbon cable. This power supply is always on when AC power is provided. So if you can probe this wire and see 33-36 volts DC, your power supply is likely fine.

Rather than carefully desoldering the 5v IC and diode, then waiting possibly weeks for working replacement parts (That may end up failing again). I elected to bypass the integrated 5v circuit and use parts that you can get next day on Amazon.

Some people have found that simply replacing the SS34B diode fixed their problem, but in my case, I de-soldered and lifted the output (pin 3) of the 5V IC and found no voltage was present, telling me the chip was bad. IF your 5v is good, and the diode is bad, you can either replace it with another SS34B, or a common 1N5822 through-hole style diode

The easiest way to remove the 5V IC is to use your side cutters to cut the legs off of the chip (Labeled U3 on the board). You will not be able to completely remove the IC from the board without a hot air station. The bottom of the chip is a ground and soldered to the PCB.

Now, de-solder the schottky SS34B diode(D1)

Find or purchase an off the shelf buck converter from a site like Amazon. I used this one

Strip some wire off of the 36v ribbon cable to solder a wire that will go to the “V+ In” on the buck converter.

Solder a wire onto the Anode side of ZD2. (You’ll see the diode, blue and orange next to the inductor labeled 220). Solder this wire to the “V- In” on the buck converter.

Turn the power supply on, and use the trim pot to adjust the output voltage to 5.00v DC.

Once you have voltage dialed in, solder a new wire onto the Cathode(blue) side of ZD2. Solder the other end of this wire to “V+ Out”

We are essentially bypassing the burnt out 5v circuit and replacing it with a buck converter.

Use Kapton tape to tape down the wires and prevent any movement or stress to the parts you soldered

Use electrical tape to cover the spliced 36v ribbon cable

Reassemble the board and test.

Board works.

Reassembled everything, tested all the functions including the app and remote control. No issues.

This guide will show you the fuse locations and equipment needed to hardwire a radar detector or dashcam on a 2022 Hyundai Elantra N

Consumables needed: Micro2 Fuse Tap (Affiliate Link)

Note: Fuse Taps are directional! For unpopulated fuse banks, only put a fuse in the top and leave the passthrough spot empty.

Fuse Locations

Fuse 47 (red wire on right) should be unpopulated. The left side will provide +12V when the car is on. Insert the fuse tap with the fuse facing down. You can use this for Radar Detectors, Remote wire for amp turn on, Dashcam, etc.

Fuse 31 (yellow wire on left) will provide the car +12v at all times. You can use this for parking mode wire

Ground Location

To allow an Allworx phone system to receive updates the following IP’s must be unblocked:

allworxportal.com (52.191.116.193)

TCP/8081

TCP/80

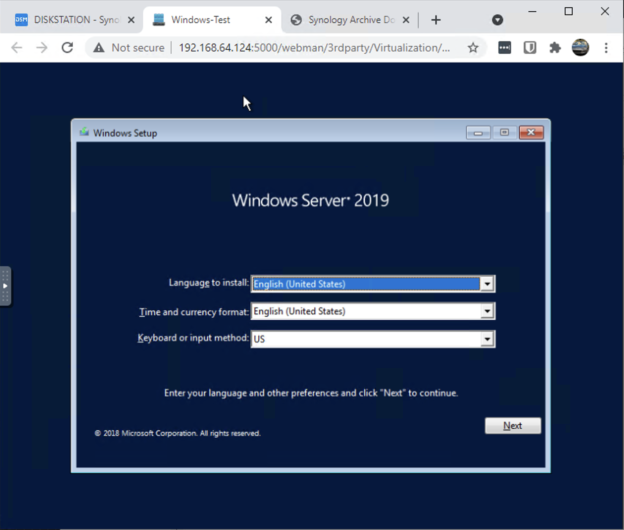

I haven’t seen anyone successfully get VMM working on an upgraded DS415+ with 8GB of RAM.

Yes. It IS possible. You have to use specific version of packages found at: https://archive.synology.com/download/Package/

Replication Service: 1.0.12-0065

Virtualization: 2.5.3-9760

I’m running DSM: 6.2.4-25556

Photos below:

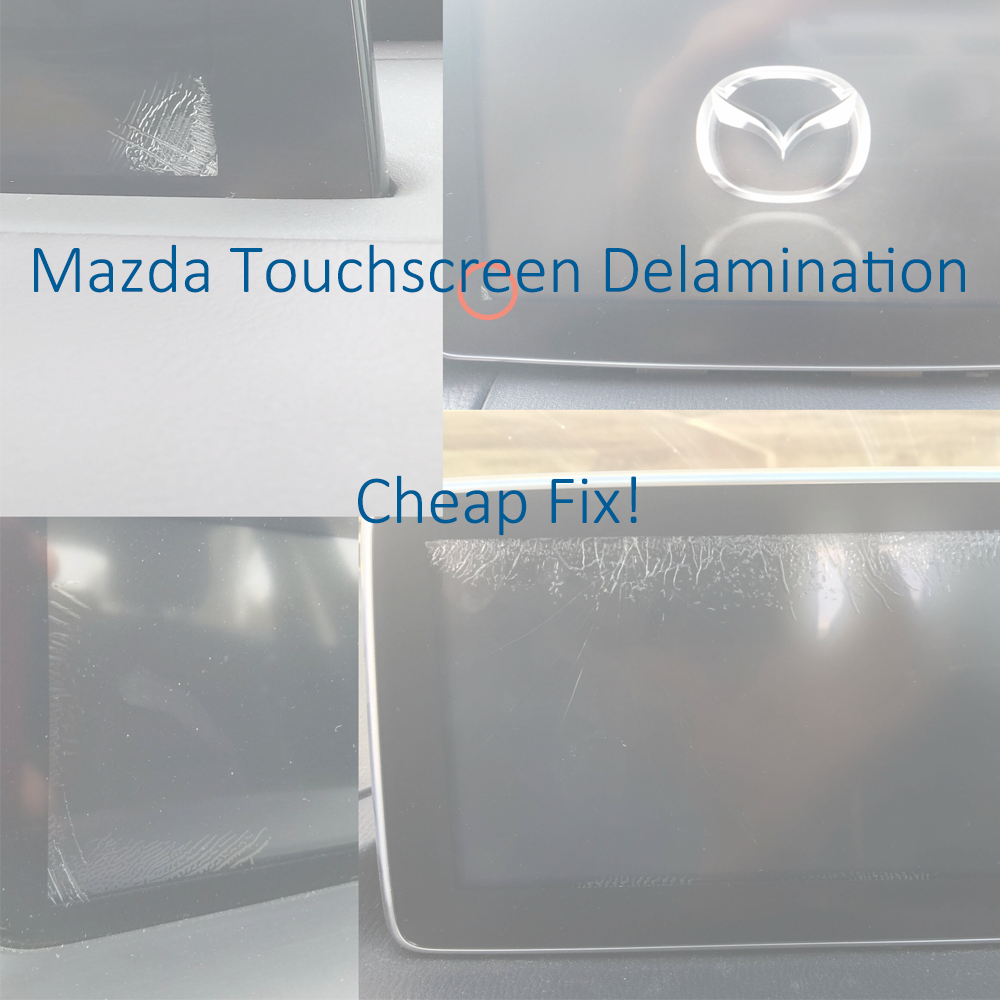

This is a guide on how to replace the touchscreen on a Mazdaconnect infotainment system.

This guide involves some basic tools and a $15-$25 part from Aliexpress. It is significantly cheaper than having a dealership replace the entire CMU ($1500+), or DIY replacing the whole screen assembly($200).

The problem: Repeated hot/cold cycles causes de-lamination of the adhesive used to combine the touchscreen cover and the digitizer. This failure was a manufacturing defect, and newer vehicles produced by Mazda do not have this problem.

If your car is experiencing any of the issues seen below, this operation may be required to resolve.

If your car is still under full warranty, you can get it replaced at no charge. Info

Note: I took these pictures while re-assembling, after fixing my screen. If something doesn’t look right, let me know. Certain steps in this guide must be done with extreme caution to not damage the screen PCB. If you are not comfortable with working on electronics, do not begin this guide.

If you found this guide helpful, please consider using the affiliate links below to purchase Tools needed for this project.

Disclosure about affiliate links: “When you click on links to various merchants on this site and make a purchase, this can result in this site earning a commission. Affiliate programs and affiliations include, but are not limited to, the eBay Partner Network.”

This guide will quickly give you very important information you need on provisioning VVX phones with FreePBX

When a phone is factory reset, it will get a DHCP lease.

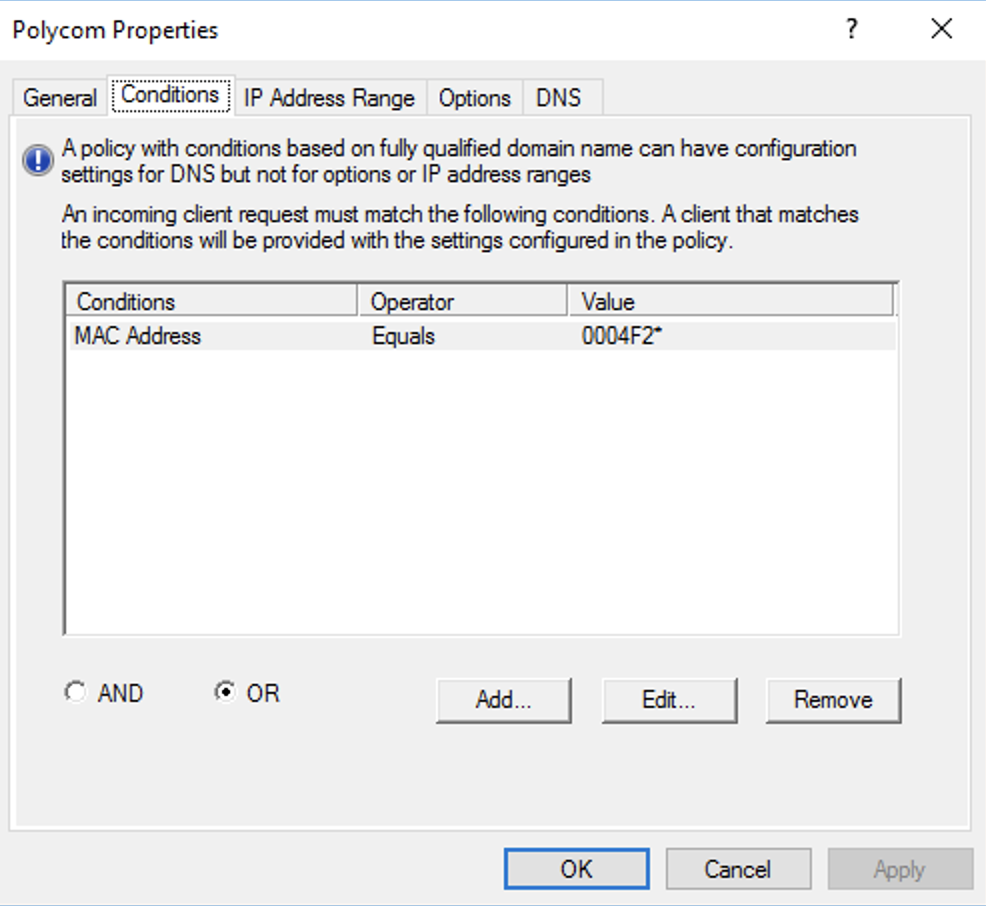

Polycom VVX phones have a mac address starting with 0004F2. You can create a policy in Windows DHCP server to allocate specific IPs to the phones

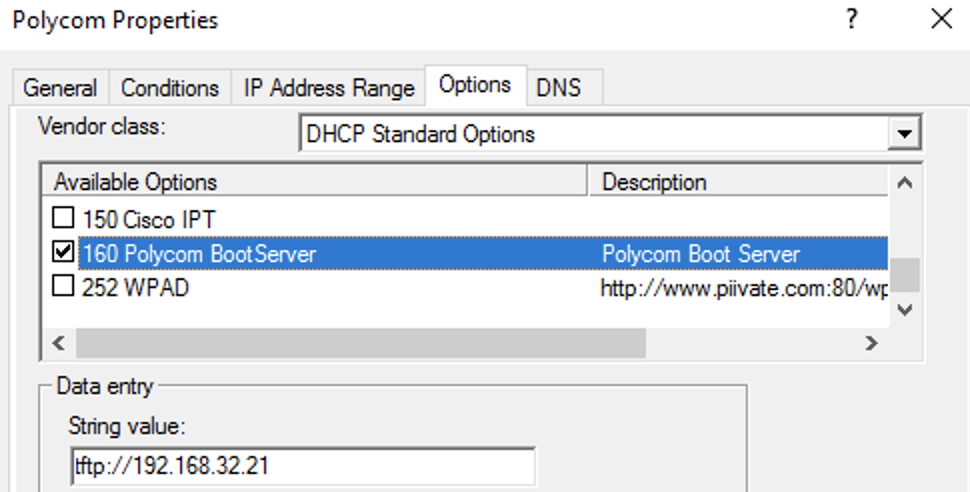

Polycom phones utilize DHCP option 160 to find a provisioning server. The contents of option 160 must be in string format. (e.g. tftp://192.168.1.10)

For time synchronization, DHCP option 42 must be set.

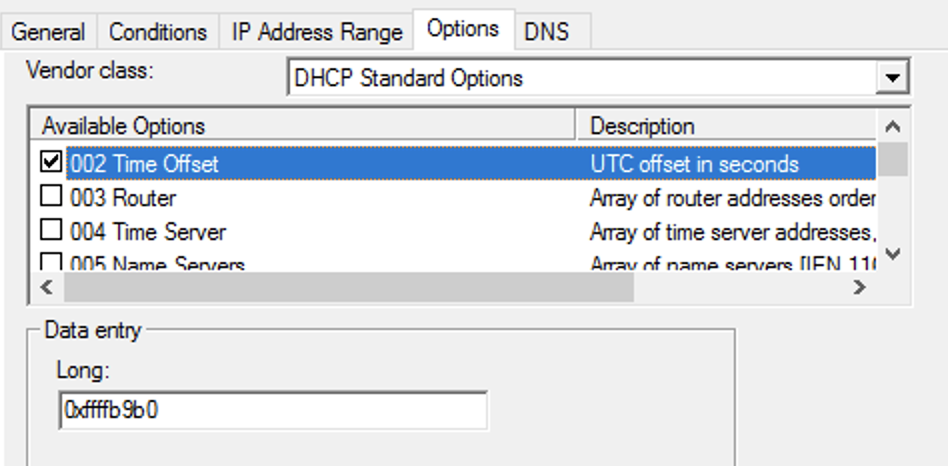

They also use DHCP option 002 to get the time offset.

I use software called Tftpd64 to create a tftp server on my windows PCs. I tell it which folder I dump all my config files into.

when the phone boots, it will look for [mac address].cfg, if it can’t find that, it will look for [mac address]-web.cfg, then 000000000000.cfg.

000000000000.cfg is supposed to be the catchall for phone provisioning. It should not contain any actual phone provisioning commands, it only helps the phone point to other configuration files.

Polycom recommends using XML Notepad by Microsoft to edit these files.

000000000000.cfg defines the following settings before the phone boots:

This is an example deployment scenario:

The following settings are important for a FreePBX Deployment

msg.mwi.1.callBackMode=”contact” – This is part of the fix for the voicemail button. By default it is set to “register”, but FreePBX requires SIP phones to call a number to get voicemail

voIpProt.SIP.AlertInfo.1.value=”Auto Answer” – When a user dials *80[ext], typically the phone will autoanswer. This is known as page/intercom mode. Special SIP headers are sent by FreePBX so the phone recognizes a page from a regular call. Setting this will make the phone aware of a page

voIpProt.SIP.AlertInfo.1.class=”ringAutoAnswer” – your polycom phone has profiles that define what ringtone to use, how many times to ring, and to auto answer. This setting will tell the phone to auto answer if the SIP.AlertInfo field equals “Auto Answer”

attendant.resourceList.1.label=”Page All” – I have my main page group set to 900 in FreePBX -> Applications -> Paging and Intercom -> Page Group. These commands will create a softkey button to page all phones in page group 900.

attendant.resourceList.1.address=”900″

attendant.resourceList.1.type=”normal”

msg.mwi.1.subscribe=”[ext]” – enter your sip extension here to get the mailbox to work

msg.mwi.1.callBack=”*98[ext]” – enter *98 and your sip extension here. This is the number that is called when the voicemail button is pressed.